Is your pressure washer not performing as expected? We understand how frustrating that can be. With our extensive knowledge and experience, we’re confident we can help you troubleshoot and resolve any issues you may face.

Greenworks Pressure Washer Troubleshooting:

To troubleshoot your Greenworks pressure washer, the first step is to identify the type of problem. Is the pressure washer not producing the correct pressure? Is the output pulsing high and low? Is there a motor or pump problem? Or is the pressure washer pump or another part of the machine leaking? Knowing the type of problem, you can use our diagnosis table to find the cause and solution.

This article will provide a complete guide to troubleshooting your Greenworks pressure washer. It will give you information about the reasons that cause the electric pressure washer not to work correctly and provide solutions to these problems.

Contents

- 1 Diagnose and troubleshoot a Greenworks Pressure Washer

- 1.0.1 I remember disassembling an entire unit to fix a motor issue. It was challenging but rewarding, and it tested my expertise. But that’s what 20 years in the field prepares you for.”

- 1.0.2 In my 20 years of experience, I’ve found that the most common issues with Greenworks pressure washers are low pressure, motor not starting, and water leaks. These problems can be daunting, but they can be resolved with patience and the right approach.

- 2 Why Does My Greenworks Water Pressure Washer Keep Shutting Off?

- 2.1 ● Step 1: Check the unloader valve

- 2.2 ● Step 2: Unplug the pressure washer

- 2.3 ● Step 3: Remove the top and take off the nob

- 2.4 ● Step 4: Lock the nuts, clip the pressure gauge, and start tightening the spring

- 2.5 ● Step 5: Adjust the knob until you find the spot where pressure is maximal and the spike is minimal

- 3 Why is My Electric Pressure Washer Not Working?

- 3.1 ● Broken Cord or Damaged Plug:

- 3.2 ● Burned Capacitor:

- 3.3 ● Blown Fuse:

- 3.4 ● Damaged Unloader Valve

- 3.5 ● Clogged Hose or Inlet Filter

- 3.6 ● Faulty Pump

- 3.7 ● Water Leaking From the Pump

- 3.8 How to Fix A Greenworks Electric Pressure Washer and Troubleshoot If It Isn’t Starting

- 3.9 ● Step 1: Check the cord and AC outlet

- 3.10 ● Step 2: Check the fuse and replace it

- 3.11 ● Step 3: Replace the capacitor

Diagnose and troubleshoot a Greenworks Pressure Washer

Use the following table to diagnose and troubleshoot a GreenWorks pressure washer:

Cause | Solution |

|---|---|

Hose with small diameter | Replace your hose with a 1″ (25mm) or 5/8″ (16mm) hose |

Restricted water supply to the washer | Check for the kinks and leaks in the hose |

Inadequate water supply | Ensure the water source is unobstructed and fully turned on |

Clogged intake filter | Remove the filter and rinse it with warm water |

Air in the pump | Ensure that the hose and fittings are airtight. Shut off the washer and squeeze the trigger until water flows steadily from the spray tip |

The suction tube or detergent bottle is not connected properly | Install the suction tube and detergent bottle correctly |

Detergent too thick | Dilute the thick detergent by adding water |

Obstructed spray tip | Remove the debris with a needle |

No pressure tip on the wand | Install a suitable pressure tip at the end of the wand |

If your model has a belt, it can be loose. | Tighten or replace the belt. |

I remember disassembling an entire unit to fix a motor issue. It was challenging but rewarding, and it tested my expertise. But that’s what 20 years in the field prepares you for.”

Problem | Cause | Solution |

|---|---|---|

Pulsing pressure washer (output pressure varies high and low) | Inadequate water supply | Ensure that the water source is fully on and check the hose for kinks and blockage |

Obstructed spray tip | Remove the debris with a needle | |

Pump sucking air | Ensure that the hose and fittings are airtight. Shut off the washer and squeeze the trigger until water flows steadily from the spray tip | |

Clogged intake filter | Remove the filter and rinse it with warm water | |

Calcified hose, tip, or trigger | Clean the hose, pressure tip, or trigger with vinegar or a cleaner designed for this purpose |

Problem | Cause | Solution |

|---|---|---|

No output pressure. Or the motor stops when using the trigger (electric models) | The power switch is in the “OFF” or “0” state | Turn the power switch “ON” or “1” |

Cord not plugged | Plugin the power cord | |

Damaged, too long, or improper extension cord | Replace the existing cord with a 25′ (7.6m) 14 AWG cord or a 50′ (15m) 12 AWG cord | |

Inadequate power from the electrical outlet | Plug the cord in a different outlet | |

The pressure washer circuit breaker tripped | Wait for the washer to cool down and restart it | |

Noisy Pump | Air in the pump | Ensure that the hose and fittings are airtight. Shut off the washer and squeeze the trigger until water flows steadily from the spray tip |

Clogged inlet filter | Remove the filter and rinse it with warm water | |

Pump leaking water | Damaged or worn water seals | Replace the seals with new ones or call a professional |

Loose fittings | Ensure that all the fitting are tight | |

Erratic water pressure, changing up and down | Unloader valve | Check and clean the unloader valve. If in bad shape, replace it |

No output pressure. Or motor stops when using the trigger (electric models) | Unloader valve | Check and clean the unloader valve. If in bad shape, replace it |

In my 20 years of experience, I’ve found that the most common issues with Greenworks pressure washers are low pressure, motor not starting, and water leaks. These problems can be daunting, but they can be resolved with patience and the right approach.

Problem | Cause | Solution |

|---|---|---|

The motor buzzes but fails to run | Damaged or broken O-rings or plastic insert | Replace the worn O-rings or call a professional |

Pressure washer dripping oil | Worn or damaged oil seals | Inspect the oil seals and replace if worn |

No water from the washer outlet | The water supply is off | Turn the water supply ON |

Kink in the hose or faucet | Remove any kinks and debris from the hose or water lines | |

Call a Professional | Loss in voltage due to the extension cord | Plug the unit directly into the outlet without an extension cord. If the problem isn’t solved, replace the extension cord |

Low supply voltage | Ensure that only the pressure washer runs on that circuit at the time of use | |

Residual pressure in the system | Shut off the washer and squeeze the trigger to release pressure | |

Residual friction among the internal components | Cut the water supply and turn the machine ON for 2 to 3 seconds. Try it a couple of times or until the motor starts. Don’t let the machine run dry for more than 3 seconds. | |

Unit not used for long periods | Call a professional |

Why Does My Greenworks Water Pressure Washer Keep Shutting Off?

A Greenworks pressure washer keeps shutting off due to a problem with the unloader valve. A faulty unloader valve doesn’t divert the water to the inlet, which increases pressure inside the pump, and the washer shuts off. This can happen in both corded and cordless models.

The unloader valve diverts the water flow towards the inlet. When the unloader valve fails to do this, a lot of pressure builds up in the powered pressure washer.

The motor, which can be battery-powered in cordless models, will be under a lot of strain, needs to supply a lot of power driving the pump, and ultimately shuts off.

To solve this problem, carefully inspect the unloader valve’s springs and other components. Greenworks Tools offers a range of replacement parts for their products. Readjust the valve or replace the damaged parts of the valve or the whole valve if it’s fully damaged.

Here is a step-by-step guide to follow if your Greenworks pressure washer, which could be one of their 47 products, keeps shutting off:

● Step 1: Check the unloader valve

The easiest way to check the unloader valve is by adjusting the spring of the unloader valve. Mark the setting before changing it. That way, you can easily set it back after changing it. When you move the spring, you should see the output pressure of the pressure washer change.

You should be able to lower it and set it higher. If this is the case, the unloader valve is working fine. Ensure that you set it to the correct level.

● Step 2: Unplug the pressure washer

For safety reasons, remove the power cord from the wall socket.

● Step 3: Remove the top and take off the nob

Remove the nut from the top of the unloader valve and take off the plastic pressure adjusting knob. Then, remove the thin washer and the spring. If you have successfully removed them, you will see a threaded piston and rod with two locking nuts.

● Step 4: Lock the nuts, clip the pressure gauge, and start tightening the spring

Lock the two nuts you see on the rod together with a wrench. Put the spring washer and black adjusting knob on. If you have a pressure gauge, attach it between the pump and the pressure hose. You can use it to see the output pressure when you press the trigger.

You must do this by sight if you do not have a pressure gauge. Try to spray at the same distance to the same spot to compare the different settings more easily.

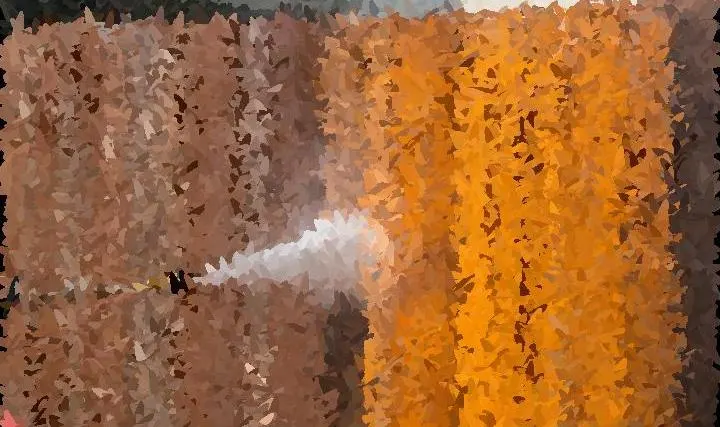

Turn the water on and press the trigger. Ensure that all the air from the pump is released and only water comes out of the nozzle.

Now press the trigger. Look at the pressure gauge. Start tightening the spring. The pressure should increase. Now, release the trigger. You will see that the pressure spikes up. The goal is to find the setting where the spike is somewhere between 5% to 10%.

This is the spot where you need to stop adjusting the knob. It would be best not to have more than a 10 % spike when you release the trigger. If it is higher, it can damage the pump over time.

For example, if you set the pressure to 3000 PSI. The pressure spike shouldn’t exceed 3240 PSI when you release the trigger.

Keep your Greenworks tools well-maintained and charged using the appropriate charger and 2.0ah USB if applicable. This will ensure the longevity of your products and keep them running efficiently.

● Step 5: Adjust the knob until you find the spot where pressure is maximal and the spike is minimal

Keep the machine running and continue adjusting the knob. If the nuts are too low, you can move them higher. Find the setting where the pressure is highest, and the spike is as low as possible. As mentioned earlier, the spike should not exceed 10%.

If possible, it should be lower if you release the trigger. Once you find the spot, take off the adjusting knob, washer, and spring, and tighten the nuts firmly with wrenches.

Crank down the spring to bottom it out on the two nuts. Recheck the pressure and spike. Suppose the pressure and spike are both ok. Screw the nut on top of the piston rod and pop the cap on top of the adjusting knob.

Over the years, Greenworks pressure washers have become more user-friendly, with clearer controls and more efficient motors. It’s a testament to the company’s commitment to continuous improvement.

Why is My Electric Pressure Washer Not Working?

The most common reasons for an electric pressure washer not to work correctly are a broken cord, a burned capacitor, or a blown fuse. These may prevent the pressure washer from running at all. The pump and the unloader valve might have an issue. Resulting in a hot motor or an irregular output pressure.

● Broken Cord or Damaged Plug:

If your electric pressure washer is not working, the first thing to check is if the power outlet is working. My experience is that, in many cases, the problem lies in the outlet or the cord. Use a lamp or another appliance to check if there is power.

Due to some moisture, the earth leakage circuit breaker may have tripped. But if the fuse has blown, there can be a more substantial problem.

It would be best to inspect the cord while troubleshooting an electric pressure washer. If you notice that if you move the cord up and down, it sometimes seems to work. It is a clear indication that the power cord is damaged.

Open the pressure washer, replace the power cord, and plug. This is a common issue in residential areas.

● Burned Capacitor:

An electric pressure washer may not start if the capacitor inside the motor is burned. Remove the outer case covering the engine with the screwdriver to inspect the capacitor. A bulging or blackening capacitor indicates damage. This needs to be replaced.

For some motors, you can return it separately. For some other engines, you need to replace the whole motor. This is a common issue when dealing with duty projects, including but not limited to heavy machinery.

● Blown Fuse:

A blown fuse in an electric pressure washer won’t allow the washer to run at all. If, for whatever reason, the pressure washer uses more power than it usually does, the fuse can blow. When replacing the fuse or resetting it in the case of an electronic version, it is important to understand that something has caused it.

Fuses do not blow for no reason. Be careful when turning on the pressure washer after replacing a fuse. This is especially important when the washer is used for tasks including but not limited to cleaning patio furniture.

If you use a large extension cord of a small gauge, your fuse might blow. Using a 12-gauge wire cord is recommended if the cord is longer than 25 feet. Extension cords with small gauges don’t provide adequate power to the pressure washer and blow a fuse. As a result, the pressure washer doesn’t start.

If your main supply voltage is low, the pressure washer’s motor pulls more current and blows a fuse. You can check the fuse of your pressure washer with a multimeter. Take the fuse out and place the multimeter probes at the ends of the fuse.

A perfect fuse has a resistance reading of almost zero. If the multimeter shows high resistance, your fuse is damaged and needs to be replaced. This is a common issue when the washer has a powerful motor and convenient push-button start.

● Damaged Unloader Valve

If your electric pressure washer produces no pressure, you may have a problem with the unloader valve. The unloader valve diverts the water flow in the pressure washer to flow back in a loop to the pump when the trigger is not pressed.

If the unloader valve gets damaged, the pressure washer produces low pressure or no pressure at all in some cases. To fix this problem, check the springs and seals of the unloader valve and replace it if it’s damaged, or try to readjust the unloader screw.

This is a common issue when the washer has a motor and convenient push-button start.

For a step-by-step approach, see the part about the unloader valve earlier in this blog post.

● Clogged Hose or Inlet Filter

This problem often arises due to an inadequate water supply. To fix this problem, ensure that the faucet is fully opened. Also, check the hose for any kinks or clogs inside. The hose connected to the pressure washer must be large enough to provide an appropriate GPM.

Check the water inlet filter and remove any debris or mineral build-up. This is a common issue when the washer is used for tasks limited to cleaning patio furniture.

● Faulty Pump

Sometimes, electric pressure washers produce a pulsating pressure. This means that the pressure frequently changes between high and low. There can be a problem with the unloader valve. But if you have checked it it is okay.

There can also be a problem with a damaged inlet, manifold, or pump valve that causes a pulsing pressure. To solve this problem, remove the pump from the washer and clean its components.

I have also seen that trapped air can result in strange behavior. You can release trapped air in the pump by pulling the trigger and letting the water flow until all the air is gone. If the problem continues, you may need to replace the pump or ask a professional for help.

● Water Leaking From the Pump

Water can leak when the pump casing isn’t sealed correctly. Or due to the activation of the thermal valve. First, check that the seals aren’t broken or worn to improve the casing seal. When this is not the case, tighten the bolts on the pump. When that does not help, replace the seals or the whole pump.

Suppose the water leakage is due to the activation of the thermal valve. Please turn off the pressure washer and let it cool down for a few minutes. Then try again. If the problem happens more frequently, determine why the pump runs hot.

How to Fix A Greenworks Electric Pressure Washer and Troubleshoot If It Isn’t Starting

Here are the steps to diagnose and fix your Greenworks electric pressure washer that won’t start:

● Step 1: Check the cord and AC outlet

Check the cord for wear and tear and ensure all the connections look okay. Check if the outlet is working with another appliance, like a lamp. If it is not working, check the earth leakage circuit breaker. Moisture can lead to tripping.

If you are using a cord with a low power rating, replace it with a cord with a higher gauge. It’s recommended to use a 12-gauge cord if its length is longer than 25 feet.

If you use an extension cable, ensure that it is not winded. Always fully unwind extension cords, as they can run really hot.

● Step 2: Check the fuse and replace it

Remove the fuse from the pressure washer and check if it’s blown. You can use a multimeter to do this. Place the multimeter’s probes at each end of the fuse and read the resistance reading on the multimeter.

A perfect fuse has approximately zero resistance reading. If you get a high rating, it means the fuse is burned and needs replacement. If your model uses an electronic fuse, reset it.

● Step 3: Replace the capacitor

Remove the case that covers the motor and check the capacitor. A blacked capacitor indicates that it’s burned. Disconnect the burned capacitor’s legs from the motor wires and install the new capacitor.

For some models, you can not replace the capacitor individually. In that case, you have to replace the whole engine.

I never knew about the unloader valve issue, good to learn about it

Glad you found the information useful, Robert! Let me know if you have any more questions regarding pressure washer troubleshooting.

I’m impressed by the depth of information provided in this troubleshooting guide

Thank you, Gloria! We strive to provide detailed troubleshooting guides to assist with any pressure washer issues. Let us know if you have any further questions or concerns.

How do I know if the unloader valve is damaged?

To determine if your unloader valve is damaged, check the output pressure, pulsing issues, and leaking. Clean, adjust, or replace the valve if necessary. Here is a guide for troubleshooting your Greenworks pressure washer.

The explanations are clear and easy to follow, great for beginners like me

Thank you, Clifton! We’re glad our explanations were helpful to you as a beginner. Feel free to reach out if you have any specific questions or need further assistance with your pressure washer troubleshooting.

Is there a warranty on Greenworks pressure washers?

Yes, Greenworks pressure washers come with a warranty. Ensure to check the details on the warranty card or contact customer support for further assistance.

Great guide, helped me troubleshoot my pressure washer easily!

Thank you, Terrence! We’re thrilled to hear our guide helped you troubleshoot your pressure washer. Feel free to reach out if you have any more questions or need further assistance. Happy cleaning!

Very detailed troubleshooting guide, thanks for the information!

Thank you, Zack! We’re glad you found our troubleshooting guide helpful. Let us know if you have any more questions or need further assistance.

My pressure washer keeps pulsing, could it be a clogged hose?

Yes, a clogged hose can indeed cause your pressure washer to pulsate. Start by checking for kinks and leaks in the hose. If the problem persists, move on to the next troubleshooting step.

Unloader valve seems to be a common issue with these. Any quick fixes?

Hi Walter, the most common issue with unloader valves can be fixed by cleaning or replacing it. Make sure to check the springs and seals as well. Let me know if you need more help!

Should I be concerned about the noise my pump is making?

If your pump is producing unusual noise, it might be a sign of a faulty unloader valve. Check and adjust it accordingly or consider replacing the damaged parts. Troubleshooting guide available if needed.

What causes a pressure washer to leak oil?

Hi Bob, a pressure washer leaking oil may have worn or damaged oil seals. Make sure to inspect and replace them if necessary. If the issue persists, consider contacting a professional for assistance.

This article has everything I need to troubleshoot my Greenworks pressure washer

Thank you, Nina! We’re glad to hear that our article helped you troubleshoot your Greenworks pressure washer. Let us know if you have any further questions or need additional assistance.

Can I use a vinegar and water solution to clean my pressure washer?

Yes, you can use a vinegar and water solution to clean your pressure washer. Just ensure you follow the proper steps to maintain your pressure washer for optimal performance.

I appreciate the detailed explanations and solutions provided in this article

Thank you for your feedback, Paula. I’m glad you found the article helpful in addressing your pressure washer issues. Let me know if you need further assistance or information.

I was able to fix my pressure washer following these steps, thanks!

Thank you for your feedback, Jane! We’re glad to hear that our troubleshooting steps helped you fix your pressure washer. Feel free to reach out if you have any more questions.

Are there specific tools I need to fix a pressure washer?

Nicholas, for Greenworks pressure washer troubleshooting, specific tools may not be needed. Understanding the problem, tools like a needle and wrench may help. Check out the complete guide on our blog for more assistance.

The step-by-step video was really helpful, made the process easier to understand

Thank you, Victor! We’re glad you found the video helpful. If you have any further questions or need assistance with troubleshooting, feel free to reach out.

What kind of maintenance should I regularly do on my pressure washer?

Regular maintenance tasks for your pressure washer include checking the water supply, cleaning filters, and ensuring fittings are tight. Refer to the diagnostics table in our troubleshooting guide for specific solutions.

The tips on maintaining the pressure washer are valuable, will keep them in mind

Thank you for your kind words, Virgil. If you ever encounter any issues with your pressure washer, feel free to reach out, and we’ll be more than happy to help you troubleshoot and resolve them.

My Greenworks washer won’t start, could it be the cord?

Hi Travis, it’s possible that your Greenworks washer issue is due to the cord. First, check the cord for any damage or wear and ensure it’s plugged in correctly. If you continue having problems, consider replacing it.